DISK CENTRIFUGE SEPARATOR

Beer Brewing Solution

Brewer’s yeast treatment

Beer Brewing Solution

The application of separators takes a new step forward in the field of beer brewing. Although separators and decanters have been used in beer production for a long time, the latest process represents a further milestone in filtration technology: beer separators and membranes are combined in a continuous flow throughout the filtration process, with maximum throughput and a simple method of type change. Protection of the environment and reduction of processing costs. In any case, disc separators and wake centrifuges play a key role in beer production. They ensure economical operation and high quality beer at key steps in the brewing process.

The application of separators takes a new step forward in the field of beer brewing.

Although separators and decanters have been used in beer production for a long time, the latest process represents a further milestone in filtration technology: beer separators and membranes are combined in a continuous flow throughout the filtration process, with maximum throughput and a simple method of type change. Protection of the environment and reduction of processing costs. In any case, disc separators and wake centrifuges play a key role in beer production. They ensure economical operation and high quality beer at key steps in the brewing process.

Beer brewing process

Beer can be produced on any scale, from small home brewing, to craft beer microbreweries and finally to large-scale industrial production. However, the brewing process is very similar on every scale.

-Recovery of beer from the bottom of the tank

Clarification of the beer before filtration

Cold wort separation

-Translation from green beer clarification

Yeast/bottom of tank

Green beer separation

Hot wort separation

-Production of non-alcoholic beer

-Rub wort separation

-Regulating turbidity with a separator

Brewer's yeast treatment

In a brewery centrifuge, also known as a beer separator or a wake-up centrifuge, these same principles apply to liquid wort or beer. This liquid contains a variety of suspended particles, including yeast, truffles and hop residues, each with a different density. As the centrifuge spins the liquid in the circular bowl at a certain speed, the heavier components of the liquid, especially yeast and must, end up near the outer walls of the bowl because they are subjected to greater centrifugal force. Meanwhile, the lightest components, including water and alcohol, will stay closer to the center axis of the rotating bowl. This centrifugal separation is further facilitated by the fact that the circumference traveled by the liquid closest to the center is much smaller than the circumference traveled by the particles along the outer wall. This even further enhances the separation of particles in the liquid according to their density. In terms of physics, the force of centrifugal force is controlled by an equation called Stokes’ Law, and brewery centrifuges are built to produce truly massive rotational forces, perhaps thousands of times the gravitational force of the earth. See Stokes’ Law. This disc-type beer separator or wake-out centrifuge also allows clear, separated liquid to be discharged from the rotating bowl while removing undissolved particles from the bowl. This is how centrifuges work in practice.

Brewery centrifuges have several uses. Wort centrifuges can separate hot wort from wort more efficiently than spin centrifuges, which are actually a low-tech centrifuge. A beer centrifuge used before packaging can separate many or most of the yeast cells from clear beer, thus reducing the turbidity of the beer. This is particularly useful if the beer is packaged unfiltered but the yeast has not flocculated sufficiently to the bottom of the fermenter. A centrifuge can be connected to an optical sensor that measures the turbidity of the beer; used correctly, this setup can be used to adjust the haze or yeast cell count at the end of the package. Similarly, a beer separator can remove some yeast between the end of primary fermentation and the start of secondary fermentation or prior to storage.

If the brewery uses concentrates, these can also be removed by a centrifuge. Another favorite location for using a centrifuge is in front of an in-line filter. Because the centrifuge removes the bulk of the particles, the filter media can perform for longer intervals before maintenance is required. Another completely different use for centrifuges is to recycle beer. When excess or used yeast slurry is removed from the bottom of the fermenter, the liquid portion of the yeast slurry is, of course, perfectly drinkable beer. Some breweries find it necessary to centrifuge the pulp and reintroduce the recovered beer into the beer stream. Finally, the beer can be centrifuged prior to packaging to remove any residual cold break. Among other things, this eliminates some of the protein-like substances that are directly or indirectly involved in haze formation and beer oxidation.

Brewer's yeast treatment

In a brewery centrifuge, also known as a beer separator or a wake-up centrifuge, these same principles apply to liquid wort or beer. This liquid contains a variety of suspended particles, including yeast, truffles and hop residues, each with a different density. As the centrifuge spins the liquid in the circular bowl at a certain speed, the heavier components of the liquid, especially yeast and must, end up near the outer walls of the bowl because they are subjected to greater centrifugal force. Meanwhile, the lightest components, including water and alcohol, will stay closer to the center axis of the rotating bowl. This centrifugal separation is further facilitated by the fact that the circumference traveled by the liquid closest to the center is much smaller than the circumference traveled by the particles along the outer wall. This even further enhances the separation of particles in the liquid according to their density. In terms of physics, the force of centrifugal force is controlled by an equation called Stokes’ Law, and brewery centrifuges are built to produce truly massive rotational forces, perhaps thousands of times the gravitational force of the earth. See Stokes’ Law. This disc-type beer separator or wake-out centrifuge also allows clear, separated liquid to be discharged from the rotating bowl while removing undissolved particles from the bowl. This is how centrifuges work in practice.

Brewery centrifuges have several uses. Wort centrifuges can separate hot wort from wort more efficiently than spin centrifuges, which are actually a low-tech centrifuge. A beer centrifuge used before packaging can separate many or most of the yeast cells from clear beer, thus reducing the turbidity of the beer. This is particularly useful if the beer is packaged unfiltered but the yeast has not flocculated sufficiently to the bottom of the fermenter. A centrifuge can be connected to an optical sensor that measures the turbidity of the beer; used correctly, this setup can be used to adjust the haze or yeast cell count at the end of the package. Similarly, a beer separator can remove some yeast between the end of primary fermentation and the start of secondary fermentation or prior to storage.

If the brewery uses concentrates, these can also be removed by a centrifuge. Another favorite location for using a centrifuge is in front of an in-line filter. Because the centrifuge removes the bulk of the particles, the filter media can perform for longer intervals before maintenance is required. Another completely different use for centrifuges is to recycle beer. When excess or used yeast slurry is removed from the bottom of the fermenter, the liquid portion of the yeast slurry is, of course, perfectly drinkable beer. Some breweries find it necessary to centrifuge the pulp and reintroduce the recovered beer into the beer stream. Finally, the beer can be centrifuged prior to packaging to remove any residual cold break. Among other things, this eliminates some of the protein-like substances that are directly or indirectly involved in haze formation and beer oxidation.

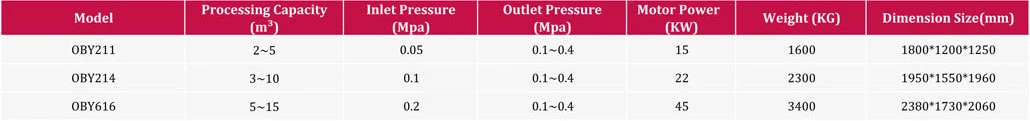

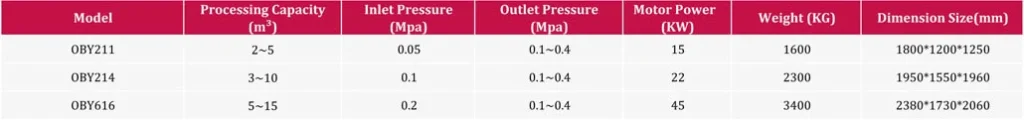

Disk Centirfuge Separator Specification

Disk Centirfuge Separator Specification

Purification |Concentration |Clarification

Solution

You want to know more about purification concentration clarification solution with customized centrifuge?

Contact us

Our experts will be happy to advise you,

when it comes to Purification / Concentration/ Clarification.

Purification |Concentration |Clarification

Solution

You want to know more about purification concentration clarification solution with customized centrifuge?

Contact us

Our experts will be happy to advise you,

when it comes to Purification / Concentration/ Clarification.